Additional Information:

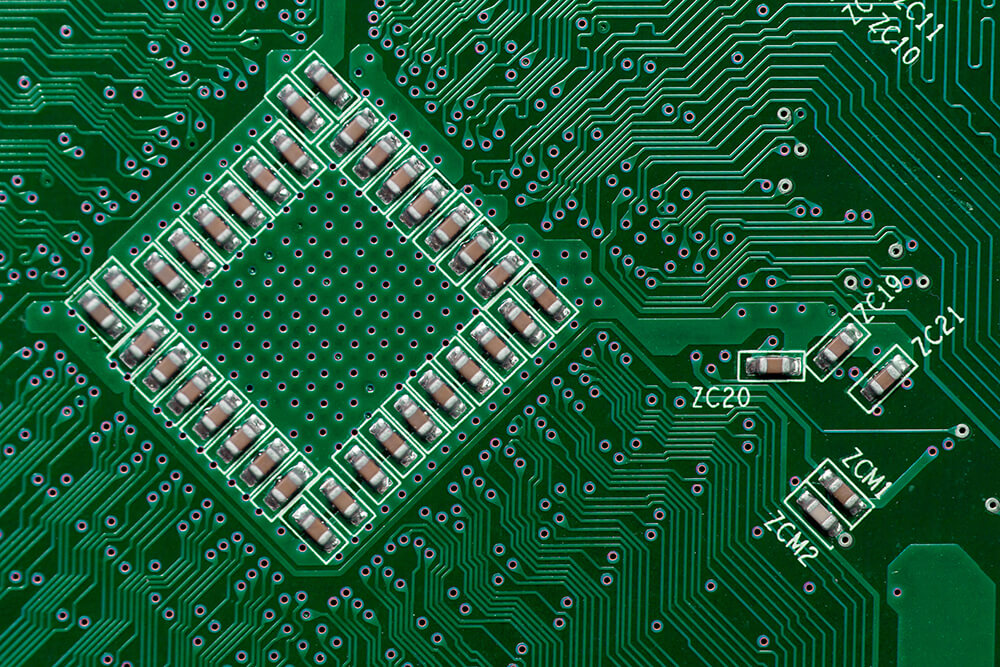

Our clients PCB production facility is a circa 3,000 square metre smart factory that is capable of board assembly, system integration, quality assurance testing and mass production of single-sided, double-sided and multi-layered PCB’s up to IPC class 3.

Their state of the art cable and wiring harness facility produce customised cable and wire harnesses, and provide engineering design services for all types of electromechanical, power supply, industrial or other uses. The harnessing production line serves customers in industries such as telecommunications, oil and gas, healthcare and defence with electronic assemblies that deliver exceptional reliability and durability

Job Title: PCB Manufacturing Director – Defense Industry

Job Summary:

As the PCB Manufacturing Director in the defense industry, you will play a pivotal role in overseeing and managing the printed circuit board (PCB) manufacturing operations for the organization. Your primary responsibility will be to ensure the efficient production of high-quality PCBs that meet the stringent standards and requirements of the defense sector. You will lead a team of skilled professionals, implement advanced manufacturing processes, and drive continuous improvement initiatives to enhance production capabilities.

Key Responsibilities:

Leadership and Team Management:

Provide strong leadership to the PCB manufacturing team, including managers, engineers, and technicians.

Foster a culture of teamwork, accountability, and continuous improvement.

Set clear goals and expectations for the team and regularly evaluate performance.

Strategic Planning:

Develop and execute a strategic plan for PCB manufacturing in alignment with the defense industry’s evolving needs and technological advancements.

Identify opportunities for growth, expansion, and diversification of PCB production capabilities.

Quality Assurance:

Ensure that PCBs meet the highest quality standards and comply with strict defense industry specifications and regulations.

Implement and maintain quality control processes, including testing and inspection procedures.

Process Optimization:

Continuously improve manufacturing processes to enhance efficiency, reduce lead times, and minimize production costs.

Stay updated with industry best practices and emerging technologies to drive innovation in PCB manufacturing.

Resource Management:

Manage the allocation of resources, including equipment, materials, and personnel, to meet production targets and deadlines.

Monitor and optimize resource utilization to maximize productivity.

Regulatory Compliance:

Ensure compliance with all relevant regulatory requirements, including ITAR (International Traffic in Arms Regulations) and other defense industry standards.

Oversee documentation and reporting to demonstrate compliance.

Supply Chain Collaboration:

Collaborate with the supply chain and procurement teams to ensure a reliable and cost-effective supply of raw materials and components.

Develop and maintain relationships with key suppliers.

Risk Management:

Identify and mitigate risks that may impact manufacturing operations, product quality, or project timelines.

Implement contingency plans to address potential disruptions.

Budget Management:

Develop and manage the PCB manufacturing budget, ensuring cost-effective operations while maintaining high-quality standards.

Monitor expenses and identify cost-saving opportunities.

Safety and Environmental Compliance:

Promote a safe working environment and ensure that all manufacturing activities adhere to safety protocols and environmental regulations.

Qualifications:

- Bachelor’s degree in Electrical Engineering, Mechanical Engineering, or a related field; a Master’s degree is preferred.

- Minimum of 10 years of experience in PCB manufacturing, with at least 5 years in a leadership or managerial role.

- Strong knowledge of PCB fabrication processes, including surface-mount technology (SMT), through-hole assembly, and multilayer PCBs.

- Familiarity with defense industry regulations and standards, such as ITAR, IPC, and MIL-PRF.

- Proven experience in process optimization and continuous improvement methodologies (e.g., Six Sigma, Lean Manufacturing).

- Excellent leadership and team management skills, with a track record of driving performance and fostering a culture of excellence.

- Exceptional problem-solving and decision-making abilities.

- Strong communication skills, both written and verbal.

- Ability to collaborate effectively with cross-functional teams and external partners.

- Project management experience is a plus.

*NB: All applicants CVS will be reviewed and should your skillset match our client’s requirements, we will contact you via email / mobile. We are also happy to consider you for other open opportunities within Firstaff. If however, you object to us holding your data on file, please acknowledge via email by return.*

Contact

Paul Dooley

Managing Director

- paul@firstaff.ie

- +353 1 679 7766

-

Firstaff Personnel Consultants

85/86 Grafton Street

Dublin 2

Ireland